News

-

Classifications and Working Principles of Rock Drilling Machines

Rock drilling machines, also known as rock drills or rock breakers, are essential tools used in various industries such as mining, construction, and exploration. This article aims to provide an overview of the basic classifications and working principles of rock drilling machines. I. Classificati...Read more -

Do You Know about Rock Drills?

Rock drills, also known as jackhammers, are powerful tools used in the construction, mining, and demolition industries. These machines are designed to break through hard rock surfaces effectively and quickly. Below, we will discuss the characteristics, applications and advantages of rock drills. ...Read more -

Features and Pros and Cons of Open-air DTH Drilling Rig

The open-air DTH drilling rig, also known as the open-air down-the-hole drilling rig, is a powerful and versatile drilling equipment widely used in various industries. In this article, we will explore the functionality, features, and advantages and disadvantages of this drilling rig. Functionalit...Read more -

Requirements for Drill Bit in Blasting Hole Drilling Operations

Blast hole drilling is a key process in various industries such as mining, construction and quarrying. The efficiency and effectiveness of this operation depend to a large extent on the quality and applicability of the drill bit used. Below, we will discuss the requirements for drill bits in blas...Read more -

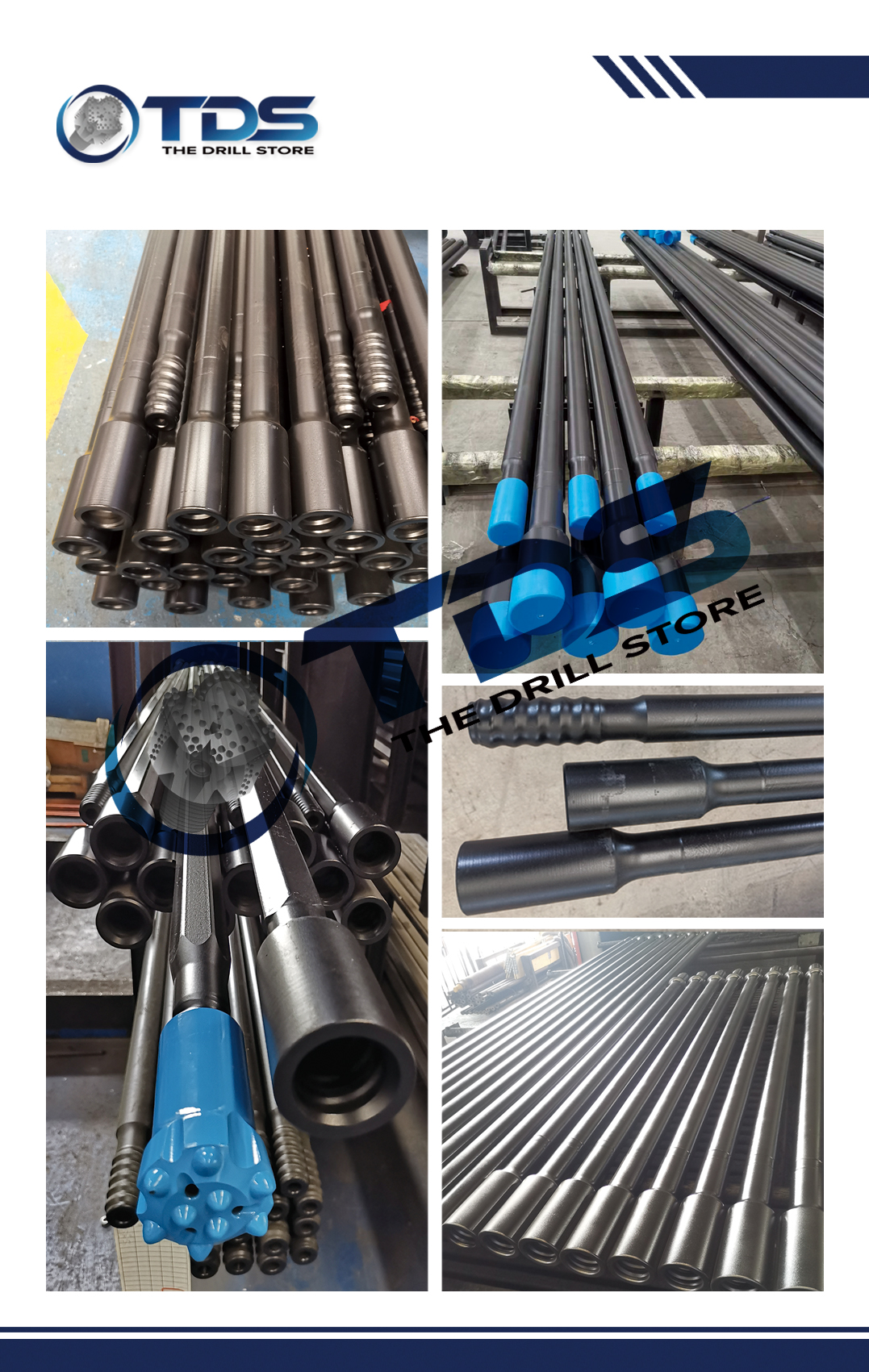

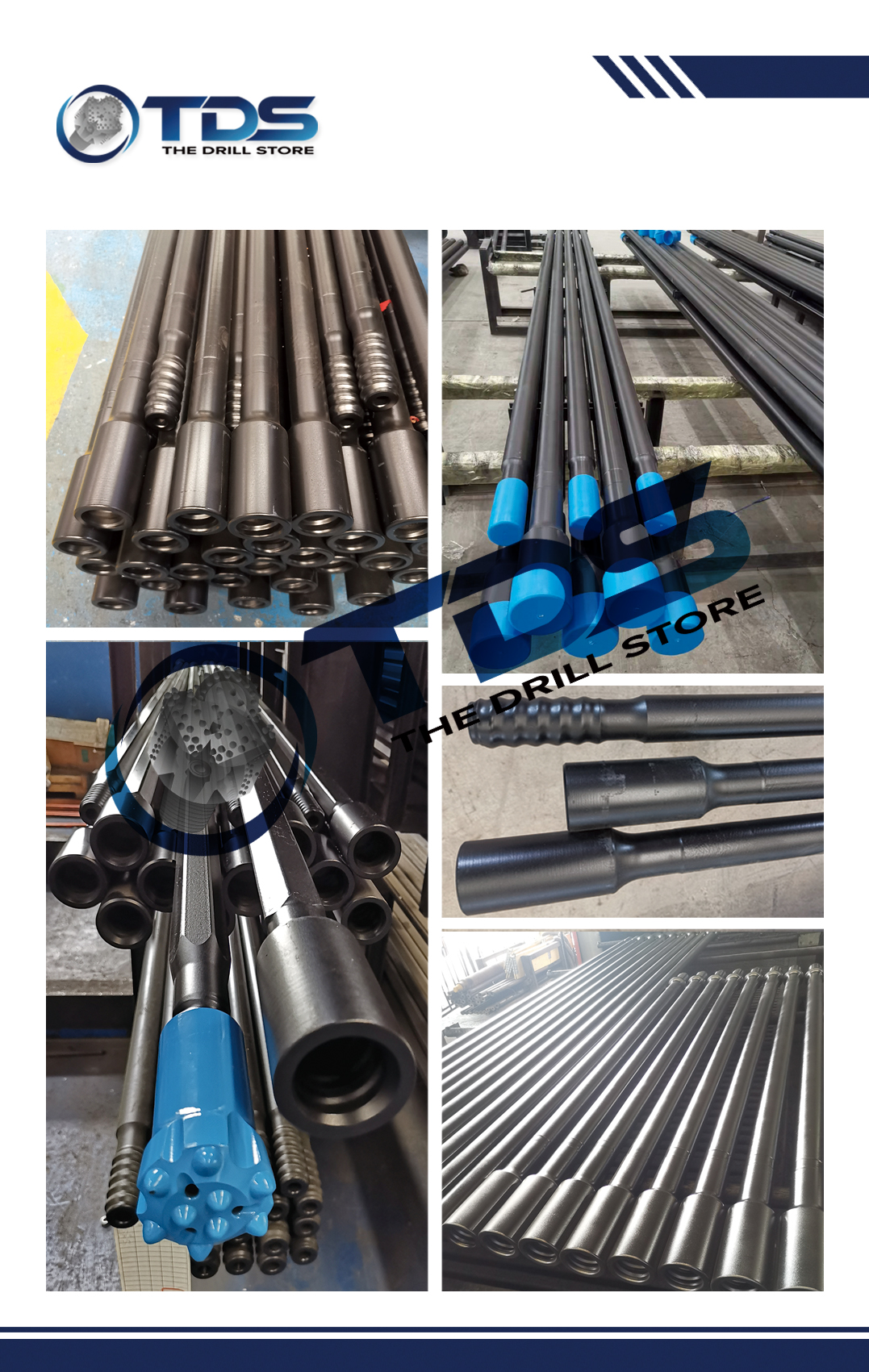

How to Choose Satisfactory Drill Rods in the Mining Industry

In the mining industry, choosing the right drill pipe is essential for efficient and effective drilling operations. One of the essential tools in this regard is the top hammer drill pipe. The following are the factors to consider when choosing a satisfactory drill pipe for mining applications. 1....Read more -

How does Top Hammer Drilling Tool Perform Rock Drilling?

Top Hammer Drilling Tool, also known as Top Hammer Drilling Equipment or Top Hammer Drill, is widely used in the mining and construction industries for rock drilling. This article will discuss how the Top Hammer Drilling Tool operates and its effectiveness in rock drilling. The Top Hammer Drillin...Read more -

Applications of Top Hammer Drilling Tools

Top hammer drilling is a widely used drilling technique in the mining, construction, and quarrying industries. This method utilizes top hammer drilling tools to deliver high-impact blows to the rock surface, resulting in efficient and productive drilling operations. In this article, we will explo...Read more -

Maintenance Procedure for Integrated Down-the-Hole Drilling Rig

The integrated down-the-hole drilling rig, also known as an all-in-one drilling rig, is a versatile and efficient piece of equipment used for drilling holes in various types of terrain. To ensure its optimal performance and longevity, regular maintenance is essential. This article will outline th...Read more -

Structure and Components of DTH Drill Rig

DTH (Down-The-Hole) drill rig, also known as a pneumatic drill rig, is a type of drilling equipment used for various applications such as mining, construction, and geotechnical exploration. 1. Frame: The frame is the main supporting structure of the DTH drill rig. It is typically made of high-str...Read more -

How Does a Down-the-Hole Drill Rig Work?

A down-the-hole drill rig, also known as a DTH drill rig, is a powerful machine used in various industries for drilling holes in the ground. It is commonly used in mining, construction, and oil and gas exploration. This article will explain how a down-the-hole drill rig works and its basic princi...Read more -

The Application Scope and Development Trends of Integrated DTH Drill Rigs

I. Application Scope of DTH Drill Rigs: 1. Mining Industry: DTH drill rigs are extensively used in surface and underground mining operations for exploration, blast hole drilling, and geotechnical investigations. 2. Construction Industry: DTH drill rigs play a crucial role in infrastructure develo...Read more -

What are the types of down-the-hole drilling rigs?

A down-the-hole drilling rig, also known as a down-the-hole drilling rig, is a kind of drilling equipment used in mining, construction, and petroleum exploration industries. These rigs are designed to drill holes in the ground by using a hammer-like mechanism to break rock or soil. There are seve...Read more