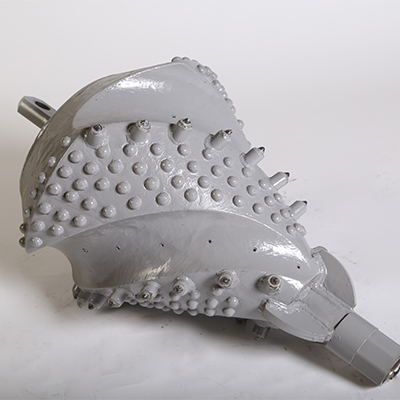

OEM Manufacturer Bw Casing - Steel Tooth Rotary Drill Bit – TDS

OEM Manufacturer Bw Casing - Steel Tooth Rotary Drill Bit – TDS Detail:

Tricone bit is an important tool for oil drilling, its work performance will directly affect the quality of drilling, drilling efficiency and drilling costs. Oil drilling and geological drilling is the most used or cone bit. The cone bit has the effect of rocking, crushing and shearing the formation rock in rotation, so the cone bit can be adapted to soft, medium and hard layers. Especially in the jet cone bit and long nozzle after the emergence of cone bit, the cone drill bit drilling speed greatly improved, is the history of the development of cone bit a major revolution. The cone bit can be divided into teeth (tooth) by tooth type, tooth (bit) (tooth set inlaid with carbide teeth) cone bit; according to the number of teeth can be divided into single cone, double , Three-cone and multi-cone bit. At home and abroad use the most, the most common is the Tricone bit.

|

SPECIFICATIONS

|

|||

|

IADC

|

WOB(KN/mm)

|

RPM(r/min)

|

Applicable Formations

|

|

417/427

|

0.3-0.9

|

150-70

|

very Soft formation with low compressive strength and high drillability,such as clay,soft mudstone,shale,salt,loose sands,etc.

|

|

437/447

|

0.35-0.9

|

150-70

|

very Soft formation with low compressive strength and high drillability,such as clay,soft mudstone,shale,salt,loose sands,etc.

|

|

515/525

|

0.35-0.9

|

180-60

|

very Soft formation with low compressive strength and high drillability,such as mudstone,salt,soft limestone, sands,etc.

|

|

517/527

|

0.35-1.0

|

140-50

|

Soft formation with low compressive strength and high drillability,such as mudstone,salt,soft limestone,sands,etc

|

|

535/545

|

0.35-1.0

|

150-60

|

medium soft with harder formation, more abrasive streaks,such as hard shale,mudstone,soft limestone,etc.

|

|

537/547

|

0.4-1.0

|

120-40

|

medium soft with harder formation, more abrasive streaks,such as hard shale,mudstone,soft limestone,etc.

|

|

617/627

|

0.45-1.1

|

90-50

|

medium hard with higher compressive strength as well as thick and hard streaks,such as hard shale,sands,limestone,dolomite,etc.

|

|

637

|

0.5-1.2

|

80-40

|

medium hard with higher compressive strength as well as thick and hard streaks,such as hard shale,sands,limestone,dolomite,etc.

|

|

737

|

0.7-1.2

|

70-40

|

Hard with high abrasiveness such as hard limestone,dolomite,firm sands,etc

|

|

827/837

|

0.7-1.2

|

70-40

|

very hard with high abrasiveness,such as quartzite,quaruzite sand,chert,basalt,granite,etc.

|

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for OEM Manufacturer Bw Casing - Steel Tooth Rotary Drill Bit – TDS , The product will supply to all over the world, such as: Uzbekistan, Buenos Aires, Australia, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.